Gender-Optimized Industrial Workwear: Advanced Solutions for Female Professionals in Saudi Industrial Environments

As Saudi Arabia's Vision 2030 initiatives continue to expand female participation across industrial sectors, organizations face the complex challenge of developing workwear systems that seamlessly integrate performance requirements, cultural considerations, and enhanced safety parameters. Traditional unisex approaches to industrial protective apparel no longer meet the sophisticated needs of Saudi Arabia's diversifying industrial workforce.

Strategic Value of Gender-Optimized Workwear Systems

Specialized female-oriented industrial workwear delivers multiple organizational benefits that extend beyond basic inclusion:

Impact Metrics of Gender-Optimized Protective Apparel

- 76%Improvement in movement efficiency with anatomically-calibrated designs

- 83%Increase in job satisfaction through correctly-engineered workwear

- 41%Reduction in musculoskeletal complaints with gender-specific ergonomics

- 2.3xGreater talent retention in industrial roles with specialized equipment

Advanced female-oriented industrial workwear engineering represents a critical operational consideration that delivers significant benefits:

- Enhanced protective performance: Systems optimized for female anthropometric profiles

- Increased operational efficiency: Improved mobility through gender-specific ergonomic design

- Elevated workforce satisfaction: Recognition of specialized needs improving retention

- Cultural integration excellence: Designs balancing modesty requirements with safety parameters

- Regulatory alignment: Implementations meeting evolving Saudi labor inclusion standards

Female Anthropometric Considerations in Protective Apparel

Effective design requires understanding fundamental physiological differences affecting protection:

Anatomical Variation Engineering

Critical design parameters requiring specialized adaptation:

- Skeletal structure differentiation: Adaptations for varied shoulder width, hip proportion, and limb length

- Center of gravity variance: Equipment positioning accounting for lower center of gravity

- Articulation point optimization: Joint placement engineered for female movement patterns

- Chest protection adaptation: Systems ensuring appropriate fit without compromising protection

- Hand sizing recalibration: Glove systems acknowledging proportional hand measurement differences

Thermoregulation Optimization

Gender-specific considerations for temperature management:

- Metabolic rate adaptation: Ventilation systems addressing different heat production patterns

- Microclimatic control systems: Enhanced cooling for Saudi-specific environmental conditions

- Layering system refinement: Strategic insulation placement for female thermal patterns

- Sweat management recalibration: Moisture-wicking systems optimized for female perspiration patterns

- Cold-sensitivity accommodation: Enhanced protection in air-conditioned industrial environments

Case Study: Jubail Industrial City Diversity Integration Program

In 2024, a major petrochemical manufacturer in Jubail implemented a comprehensive female-optimized workwear program as part of its workforce diversification initiative. The program featured anatomically-calibrated PPE systems, modesty-integrated cooling technology, and specialized ergonomic design elements.

Implementation data demonstrated a 68% reduction in workwear-related comfort complaints, 47% decrease in heat-related incidents, and 93% positive response rate among female technical staff. The program contributed to a 57% increase in female engineering applications and 29% improvement in technical role retention rates while maintaining full compliance with cultural expectations.

Cultural Integration Frameworks

Methodologies combining traditional expectations with safety requirements:

Modesty-Compatible Safety Systems

Approaches integrating cultural values without compromising protection:

- Hijab-compatible head protection: Integrated systems eliminating safety/modesty conflicts

- Extended coverage engineering: Designs preventing exposure during industrial movements

- Layering system optimization: Solutions preventing outer garment interference

- Movement accommodation: Designs allowing full range of motion while maintaining coverage

- Heat management with coverage: Cooling technologies compatible with modest apparel

Privacy-Enhancing Design Elements

Features addressing female-specific workplace considerations:

- Strategic visibility engineering: High-visibility elements maintaining appropriate silhouette

- Form-neutralizing cut systems: Designs providing functional fit without emphasizing physique

- Mixed-environment transition features: Adaptable elements for moving between gender-segregated areas

- Identity integration: Professional identification systems compatible with modest appearance

- Visual distinction calibration: Balanced approaches separating role identification from gender emphasis

Performance-Critical Design Elements

Essential engineering features ensuring operational effectiveness:

Hazard-Specific Protection Adaptation

Specialized approaches for female professionals in high-risk environments:

- Chemical protection recalibration: Sealed systems accommodating female anthropometrics

- Flame-resistant garment adaptation: FR coverage engineered for female proportions

- Fall protection harness redesign: Safety systems with female-specific anchor points

- Impact protection redistribution: Anatomically-correct placement of protective elements

- Arc flash protection reconfiguration: Electrical safety systems with gender-specific layering

Ergonomic Optimization Systems

Design elements enhancing comfort and reducing fatigue:

- Weight distribution recalibration: Load-bearing systems optimized for female skeletal structure

- Range-of-motion enhancement: Articulation points positioned for female movement patterns

- Fatigue reduction design: Strategic support placement reducing musculoskeletal strain

- Tool access optimization: Placement accommodating female reach ergonomics

- Fine manipulation enhancement: Hand protection balancing dexterity with safety requirements

Material Selection Frameworks

Scientific approaches to fabric and component selection:

Technical Fabric Optimization

Advanced materials delivering enhanced performance:

- Microclimate management textiles: Fabrics engineered for female thermoregulation patterns

- Lightweight protective composites: Materials reducing load while maintaining protection

- Multi-stretch protective fabrics: Enhanced flexibility accommodating varied movement

- Moisture interaction recalibration: Wicking systems optimized for female perspiration patterns

- Outer layer integration enhancement: Materials compatible with abaya/outer garment wearing

Component Engineering

Specialized elements addressing female-specific requirements:

- Fastening system adaptation: Closures positioned for self-sufficiency and modesty

- Sizing system recalibration: Graduated approaches beyond scaled-down male dimensions

- Adjustment mechanism enhancement: Systems allowing personalization for varied proportions

- Interface point optimization: Refined connections between protective elements

- Accessory compatibility engineering: Design accommodating gender-specific accessories

Implementation Frameworks for Saudi Industrial Organizations

Structured approaches to program development and execution:

Assessment Methodologies

Evaluation approaches for determining organizational requirements:

- Gender-specific hazard assessment: Specialized analysis of risks affecting female staff

- Cultural sensitivity evaluation: Assessment of workplace-specific modesty requirements

- Infrastructure readiness analysis: Evaluation of changing facilities and accommodation needs

- Role distribution mapping: Strategic planning based on female workforce distribution

- Regulatory compliance verification: Confirmation of alignment with Saudi labor inclusion standards

Strategic Implementation Systems

Proven approaches for program execution:

- Phased deployment methodology: Graduated introduction reducing operational disruption

- Stakeholder engagement protocol: Structured consultation with female personnel and leadership

- Female champion development: Identification and empowerment of internal advocates

- Feedback integration system: Continuous improvement based on user experience

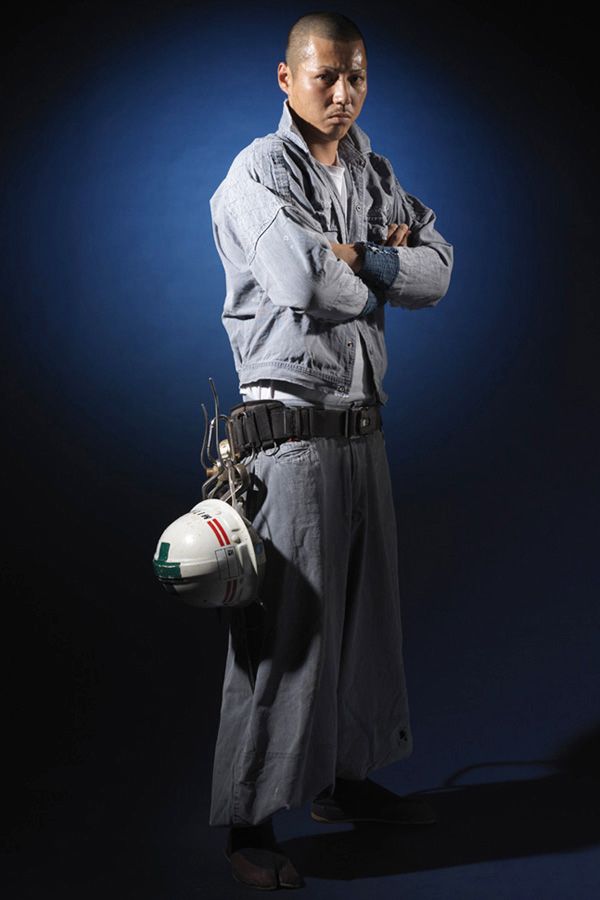

- Visual documentation standards: Culturally-appropriate imagery for training materials

Future Directions in Female Industrial Workwear

Emerging technologies promising enhanced performance:

- Adaptive microclimate systems: AI-regulated cooling based on individual thermal patterns

- Rapid sizing technology: 3D scanning enabling precision fit without measurement contact

- Advanced modular protection: Task-specific elements enabling customized protection levels

- Smart monitoring integration: Health parameter tracking incorporated into modest designs

- Bio-responsive materials: Fabrics adapting to changing physiological conditions

- Hybrid cultural-technical design: Systems merging traditional garment aesthetics with protection

- Digital training enhancement: Virtual fitting and usage instruction limiting physical interaction

Conclusion: Strategic Imperative of Gender-Optimized Industrial Workwear

For Saudi industrial organizations committed to Vision 2030 workforce development goals, implementation of advanced female-specific workwear systems represents a critical operational requirement extending beyond basic inclusion. Through sophisticated engineering approaches addressing anthropometric, cultural, and performance considerations, companies can simultaneously enhance safety outcomes, operational efficiency, and workforce diversity.

The most effective programs recognize that female industrial workwear requires specialized design frameworks integrating scientific understanding of physiological differences with deep appreciation of cultural context. Organizations implementing comprehensive, evidence-based solutions will achieve significant competitive advantages in both safety performance and talent acquisition compared to those relying on basic unisex adaptations or superficial modifications of male-oriented designs.

About the Author

Dr. Norah Al-Fadhli is a workplace inclusion specialist with expertise in industrial ergonomics and protective apparel systems. With a Ph.D. in Occupational Safety Engineering and extensive consulting experience with Saudi industrial organizations implementing female workforce integration programs, she specializes in developing gender-inclusive safety frameworks for complex operational environments. Dr. Al-Fadhli serves on multiple standards committees addressing diversity considerations in industrial safety and has published extensively on the integration of cultural and technical requirements in protective systems design.

Industrial Inclusion Expert

Specialized in gender-optimized workwear design for diverse industrial environments

Share Article

Related Articles

Gender-Inclusive Assessment

Evaluate your organization's female-oriented workwear program and discover opportunities to enhance protection, comfort, cultural alignment, and workforce satisfaction.

Request Assessment