In Saudi Arabia's rapidly expanding industrial sector, the proper fit of workwear and safety uniforms is not merely a comfort consideration—it's a critical safety factor with direct impacts on worker protection, productivity, and operational efficiency. This comprehensive guide examines why properly fitted industrial uniforms matter, how to achieve optimal sizing, and strategies for implementing effective uniform programs in Saudi industrial environments.

The Safety Implications of Proper Uniform Fit

Industrial environments present numerous hazards that proper-fitting uniforms help mitigate. Scientific research and industry experience consistently demonstrate that ill-fitting workwear significantly increases accident risk.

Hazard Protection Compromises

Improperly fitted uniforms undermine intended safety functions:

- Excessive Material: Loose or oversized garments can catch in moving machinery, causing entanglement hazards

- Inadequate Coverage: Undersized uniforms may expose skin to chemical splashes, thermal hazards, or abrasions

- Protective Equipment Integration: Poor fit interferes with proper PPE use and function

- Restricted Movement: Tight uniforms limit range of motion, potentially creating unsafe workarounds

- Thermal Protection Reduction: Improper layering or fit reduces effectiveness of FR (flame-resistant) garments

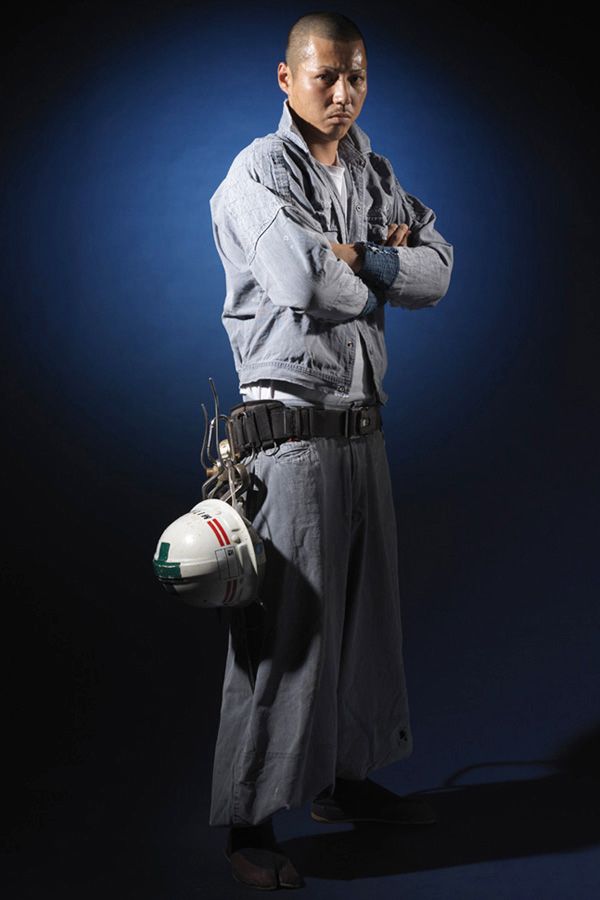

Visual representation of common safety hazards resulting from improperly fitted industrial workwear

Movement and Ergonomic Considerations

Worker movement patterns significantly influence safety profiles:

- Task-Specific Movements: Uniforms must accommodate bending, stretching, climbing, and kneeling without restriction

- Repetitive Motion Protection: Properly positioned seams and reinforcements prevent abrasion during repeated tasks

- Balance and Stability: Ill-fitting footwear or heavy, unbalanced clothing affects worker stability on elevated surfaces

- Emergency Response Capability: Garments must allow rapid movement in emergency situations

- Saudi Environmental Factors: Extreme temperature conditions require specific fit considerations for cooling and heat protection

The Productivity Impact of Workwear Fit

Performance Efficiency Correlation

Studies from industrial psychology and occupational health consistently demonstrate the productivity impacts of uniform fit:

- Discomfort Distraction: Workers dealing with ill-fitting uniforms experience cognitive distraction, reducing focus

- Movement Limitation: Restricted motion increases time required for physical tasks

- Fatigue Acceleration: Compensating for poor fit increases physical exertion and speeds onset of fatigue

- Task Avoidance: Workers may avoid certain body positions or movements due to uniform limitations

- Heat Stress Factors: Particularly relevant in Saudi Arabia, proper fit influences thermal regulation and heat stress prevention

Case Study: Sizing Program Implementation at Saudi Petrochemical Facility

A major petrochemical plant in Jubail implemented a comprehensive uniform fitting program after analyzing incident reports that indicated ill-fitting uniforms were a contributing factor in 23% of safety incidents. The program included individual measurements, customized sizing, and quarterly fit checks. Within 18 months, uniform-related incidents decreased by 78%, worker satisfaction increased by 64%, and importantly, heat-related productivity losses during summer months decreased by 31%. The plant's safety director reported that the program's ROI exceeded 300% when accounting for reduced lost-time incidents, improved productivity, and decreased uniform replacement costs.

Psychological Comfort and Professional Performance

Beyond physical considerations, uniform fit affects cognitive and psychological aspects of work:

- Professional Identity: Well-fitted uniforms enhance workers' sense of professional identity and role alignment

- Confidence Effects: Proper fit increases confidence in protection and movement capabilities

- Team Integration: Consistently well-fitted uniforms across teams promote cohesion and equality

- Pride and Compliance: Workers take greater pride in properly fitted uniforms, increasing compliance with uniform policies

- Comfort Association: Workers associate physical comfort with company respect and concern for their wellbeing

Key Dimensions of Proper Industrial Uniform Fit

Technical Fit Considerations

Proper industrial uniform fit encompasses multiple technical dimensions:

- Circumference Measurements: Chest, waist, hips, and limbs must accommodate both static positions and dynamic movement

- Vertical Dimensions: Critical length measurements including torso, inseam, sleeve, and overall garment length

- Range of Motion Allowances: Additional material allocated strategically for movement without compromising safety

- Layering Accommodation: Sizing that accounts for required base layers, mid-layers, or cooling vests in Saudi climate conditions

- Weight Distribution: Even distribution of garment weight, especially for specialized protective clothing

Essential measurement points for accurate industrial uniform sizing in Saudi industrial applications

Cultural and Gender Considerations in the Saudi Context

Saudi industrial environments require additional fit considerations:

- Cultural Modesty Requirements: Uniform designs that maintain appropriate coverage while ensuring safety

- Demographic Diversification: As more Saudi women enter industrial roles, appropriate fitting programs that respect cultural norms

- Religious Accommodation: Designs that work with head coverings and other religious attire without creating safety issues

- International Workforce Integration: Sizing systems accommodating diverse body types in multinational workforces

- Traditional Garment Adaptation: Modifications allowing integration of traditional Saudi elements where safety permits

Implementing Effective Industrial Uniform Fitting Programs

Professional Measurement Systems

World-class industrial facilities implement systematic fitting approaches:

- Individual Measurement Sessions: Professional measurement by trained staff rather than generic size assignments

- Digital Measurement Technology: 3D body scanning for precise sizing data across multiple dimensions

- Dynamic Assessment: Evaluation of uniform fit during simulated work movements and tasks

- Ongoing Monitoring: Regular re-measurement as worker body composition changes

- Privacy Protocols: Culturally appropriate measurement processes respecting Saudi norms

Sizing Standards and Specification Systems

Effective industrial uniform programs require comprehensive sizing infrastructure:

- Standardized Size Matrices: Clearly defined size ranges with consistent incremental progression

- Measurement Documentation: Detailed recording of individual worker measurements

- Garment Specification Sheets: Technical documents detailing exact measurements for each garment and size

- Variance Tolerances: Defined acceptable manufacturing variation limits to maintain fit consistency

- Comparative Guidelines: Cross-referencing between different manufacturer sizing systems

Special Considerations for Saudi Industrial Environments

Climate Adaptation in Uniform Fit

Saudi Arabia's extreme climate creates unique fit requirements:

- Heat Management Allowances: Ventilation zones and cooling space without compromising protection

- Seasonal Adjustment: Different fit requirements between extreme summer and winter conditions

- Cooling Technology Integration: Accommodation for cooling vests or systems in extreme temperature environments

- Hydration Access: Uniform design facilitating access to hydration systems without removal

- Sand and Dust Protection: Proper closure systems that prevent intrusion while maintaining comfort

Expert Guidance: Measuring for Heat Management

"When fitting industrial uniforms for Saudi environments, we recommend an additional 1.5-2cm allowance in critical movement areas to facilitate air circulation without compromising safety. This slight increase in specific measurement points significantly improves thermal regulation while maintaining protection standards."

- Mohammed Al-Abdali, Industrial Uniform Specialist with 20+ years in Saudi petrochemical safety equipment

Industry-Specific Fit Requirements

Different Saudi industrial sectors have specialized fit considerations:

- Oil & Gas: FR garment fit ensuring full coverage during climbing, confined space entry, and valve operation

- Construction: Abrasion point reinforcement and full ROM for overhead work and material handling

- Manufacturing: Close-fitting in machinery areas without movement restriction

- Chemical Processing: Proper fit around closures to prevent chemical intrusion

- Mining & Minerals: Dust seal effectiveness at closures and interfaces with respiratory equipment

Organizational Implementation Strategies

Procedural Framework for Saudi Industries

Implementing proper fit programs requires systematic approaches:

- Initial Assessment: Comprehensive evaluation of current uniform fit issues and incident correlation

- Stakeholder Engagement: Involving safety teams, operations management, and worker representatives

- Measurement Protocols: Establishing culturally appropriate measurement systems and schedules

- Supply Chain Integration: Partnering with manufacturers offering appropriate sizing ranges

- Ongoing Monitoring: Systematic review of uniform condition, worker feedback, and incident correlation

Return on Investment Analysis

Proper fit programs deliver measurable financial benefits:

- Incident Reduction: Decreased accidents and near-misses directly attributable to uniform issues

- Productivity Increases: Improved work efficiency and reduced discomfort breaks

- Uniform Longevity: Extended garment life through proper wear patterns and reduced stress points

- Compliance Improvement: Higher rates of proper uniform usage reducing regulatory risks

- Worker Retention: Increased satisfaction reducing turnover in skilled industrial positions

Conclusion

Proper fit in industrial uniforms represents a critical intersection of safety science, productivity optimization, and worker wellbeing. For Saudi industrial organizations navigating complex operational environments, extreme climate conditions, and diverse workforce considerations, implementing comprehensive uniform fitting programs delivers significant safety improvements, efficiency gains, and competitive advantages.

By treating proper fit as a strategic safety initiative rather than a simple supply issue, forward-thinking Saudi industrial operators are simultaneously enhancing protection, improving worker comfort and satisfaction, and optimizing operational performance. The investment in proper measurement, specification, and monitoring systems consistently delivers returns through reduced incidents, improved productivity, and strengthened safety culture.