Saudi Arabia's ambitious Vision 2030 is driving unprecedented growth across key industrial sectors including construction, manufacturing, oil & gas, and logistics. This industrial expansion necessitates specialized workwear solutions that prioritize worker safety, durability, and compliance with evolving KSA regulations. This comprehensive 2025 guide delves into the specific uniform needs of these critical industries, highlighting best practices for material selection, design, and safety features tailored to the demanding Saudi operational environment.

The Strategic Importance of Specialized Industrial Uniforms in KSA (SEO Keyword: Industrial Uniforms Saudi Arabia)

Properly designed industrial uniforms are not merely clothing; they are essential personal protective equipment (PPE) that contribute to:

- Worker Safety & Health: Protecting against specific workplace hazards such as heat, flames, chemicals, cuts, and impacts. This is paramount as KSA aims to achieve world-class occupational safety standards.

- Operational Efficiency: Comfortable and functional uniforms enhance worker productivity and reduce fatigue, especially in KSA's challenging climate.

- Regulatory Compliance: Adherence to Saudi labor laws, SASO standards, and industry-specific regulations (e.g., ARAMCO standards for oil & gas).

- Corporate Image & Professionalism: Uniforms project a professional image, fostering team cohesion and brand identity.

- Environmental Considerations: Increasingly, sustainable and durable materials are sought to align with KSA's environmental goals.

🏗️ 2025 KSA Industrial Sector Uniform Insights

- 40%Projected growth in KSA industrial workforce by 2030

- 150+New SASO standards for PPE and workwear

- 90%Companies prioritizing climate-specific workwear

- Top 4Industries: Construction, Manufacturing, Oil & Gas, Logistics

Uniform Needs for Key KSA Industries:

1. Construction Sector (SEO Keyword: KSA Construction Workwear)

KSA's giga-projects (NEOM, Red Sea Global, etc.) demand robust and highly functional workwear.

- Key Hazards: Sun exposure, heat stress, falling debris, sharp objects, dust, heavy machinery.

- Essential Uniform Features:

- High-Visibility Clothing: Bright colors (fluorescent yellow/orange) with retroreflective tape (SASO GSO ISO 20471). Crucial for large, busy sites.

- Durable Fabrics: Heavy-duty cotton, canvas, or ripstop polyester/cotton blends that resist tearing and abrasion.

- Sun Protection: Long sleeves, wide-brimmed hats or neck shades, UPF-rated fabrics.

- Breathability & Moisture Wicking: Lightweight, breathable materials to combat heat stress.

- Reinforcements: Double-stitched seams, reinforced knees and elbows.

- Safety Footwear: Steel-toe boots with puncture-resistant soles (SASO ISO 20345).

- Pockets & Tool Loops: Functional pockets for tools and communication devices.

- Image: [`public/images/industrial/Construction_site_uniforms.jpeg`](public/images/industrial/Construction_site_uniforms.jpeg)

2. Manufacturing Sector (SEO Keyword: Manufacturing Uniforms KSA)

Diverse manufacturing base from petrochemicals to food processing requires tailored solutions.

- Key Hazards: Machinery entanglement, chemical exposure, heat, sparks, static electricity, product contamination (food/pharma).

- Essential Uniform Features:

- Snag-Resistant Design: No loose parts, cuffed sleeves and ankles to prevent entanglement.

- Chemical Resistance: Specialized fabrics (e.g., treated polyester, polypropylene) for specific chemical exposures.

- Flame Resistance (FR): For environments with fire or arc flash risks (NFPA 2112, IEC 61482-2). ([Link to FR clothing article])

- Anti-Static Properties: ESD (Electrostatic Discharge) safe garments for electronics manufacturing or flammable environments (IEC 61340). ([Link to anti-static article])

- Hygienic Materials: For food processing and pharmaceuticals, non-shedding, easily sanitized materials.

- Comfort & Durability: For long shifts and repetitive tasks.

- Image: [`public/images/industrial/Factory_uniforms.jpeg`](public/images/industrial/Factory_uniforms.jpeg)

3. Oil & Gas Sector (SEO Keyword: Oil and Gas Uniforms Saudi)

One of KSA's most critical and hazardous industries, demanding the highest safety standards (often ARAMCO-specified).

- Key Hazards: Fire, explosion, chemical exposure (H2S), extreme heat, static electricity, visibility issues.

- Essential Uniform Features:

- Inherently Flame-Resistant (IFR) Fabrics: Modacrylic, aramid blends (e.g., Nomex®, Kevlar®) offering permanent FR protection.

- Anti-Static Properties: Essential in potentially explosive atmospheres.

- High Visibility: Often yellow/orange with reflective stripes for visibility on sprawling sites.

- Chemical Splash Protection: Specific coatings or fabric treatments.

- Durability & Tear Resistance: For rugged field conditions.

- Breathability & Moisture Management: Critical for managing heat stress under heavy PPE.

- H2S Monitor Pockets: Specialized pockets for gas detection devices.

- Image: [`public/images/industrial/Oil_and_Gas_sector_uniforms_Oilfield_workwear.jpeg`](public/images/industrial/Oil_and_Gas_sector_uniforms_Oilfield_workwear.jpeg)

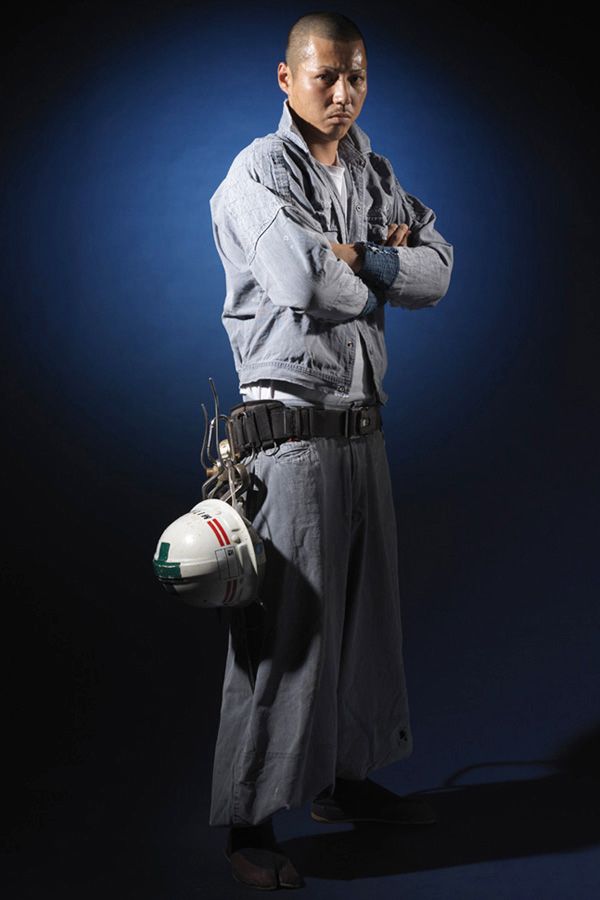

4. Logistics & Transportation Sector (SEO Keyword: Logistics Workwear KSA)

KSA's role as a global logistics hub is expanding, increasing the need for specialized workwear.

- Key Hazards: Vehicle traffic, low light conditions, manual handling injuries, weather exposure.

- Essential Uniform Features:

- High-Visibility Elements: Especially for warehouse staff, airport ground crew, and delivery drivers.

- Comfort & Freedom of Movement: For active roles involving lifting and driving. Stretch fabrics are beneficial.

- Durability: To withstand wear and tear from frequent movement and contact with goods/equipment.

- Weather Protection: Lightweight, breathable outerwear for rain or cooler nighttime temperatures. Sun protection for daytime outdoor work.

- Professional Appearance: For customer-facing roles (e.g., delivery drivers).

- Reinforced Pockets: For scanners, documents, and tools.

- Image: [`public/images/industrial/warehouse_staff_uniforms.jpeg`](public/images/industrial/warehouse_staff_uniforms.jpeg)

Cross-Industry Considerations for KSA Industrial Uniforms

- Climate Adaptability: All industrial uniforms in KSA must prioritize heat stress management through breathable fabrics, moisture-wicking technology, and appropriate design (e.g., vented backs).

- Cultural Appropriateness: Designs should respect local customs, offering options for modesty where required, without compromising safety.

- Durability & Longevity: Investing in high-quality, durable uniforms reduces long-term costs and ensures consistent protection.

- Ease of Care: Uniforms should be easy to launder and maintain, especially for large workforces. Industrial laundry compatibility is often a plus. ([Link to industrial laundry article])

- Customization & Branding: Incorporating company logos and identification while maintaining safety standards.

Conclusion: Equipping KSA's Industrial Workforce for Success and Safety

Selecting the right uniforms for Saudi Arabia's diverse industrial sectors is a critical investment in worker safety, productivity, and regulatory compliance. As KSA continues its industrial transformation under Vision 2030, partnering with knowledgeable uniform suppliers who understand the specific hazards, environmental conditions, and regulatory landscape of each sector is essential. By prioritizing high-quality, purpose-built workwear, companies can protect their most valuable asset – their workforce – and contribute to the Kingdom's journey towards industrial excellence.

Key Takeaways for KSA Industrial Uniforms

- Prioritize hazard-specific protection for each industry (FR, chemical, hi-vis, anti-static).

- Select materials and designs optimized for KSA's extreme climate conditions.

- Ensure compliance with Saudi Labor Law, SASO standards, and relevant international codes.

- Invest in durability and quality to maximize lifespan and long-term value.

- Consider cultural appropriateness and worker comfort in all designs.

- Partner with experienced suppliers for tailored workwear solutions.

About the Author

Eng. Faisal Al-Harbi is an Occupational Safety and Health (OSH) consultant with over 15 years of experience specializing in industrial PPE and workwear solutions for major projects across Saudi Arabia. He has advised companies in the construction, oil & gas, and manufacturing sectors on implementing best-practice uniform programs compliant with KSA regulations.